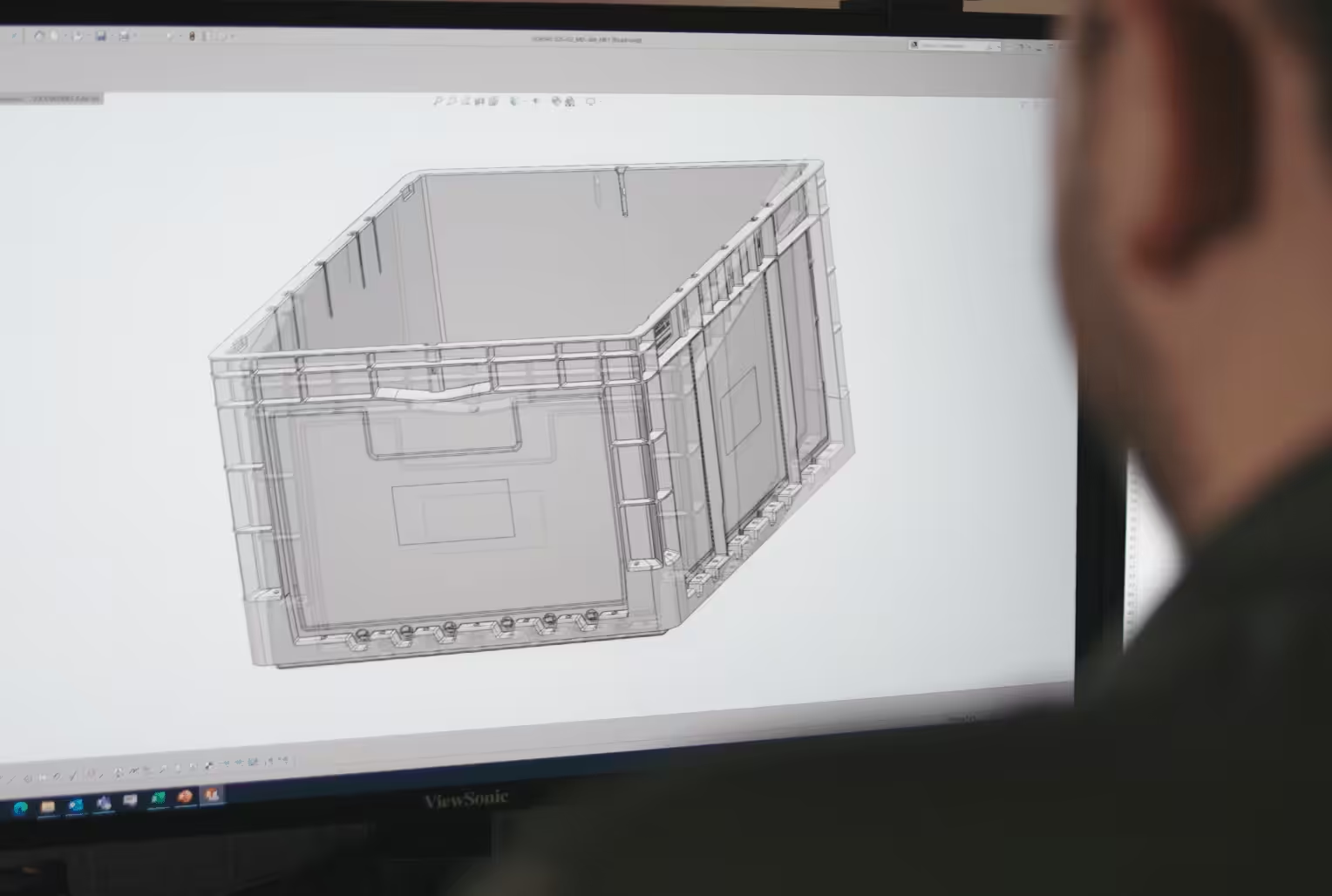

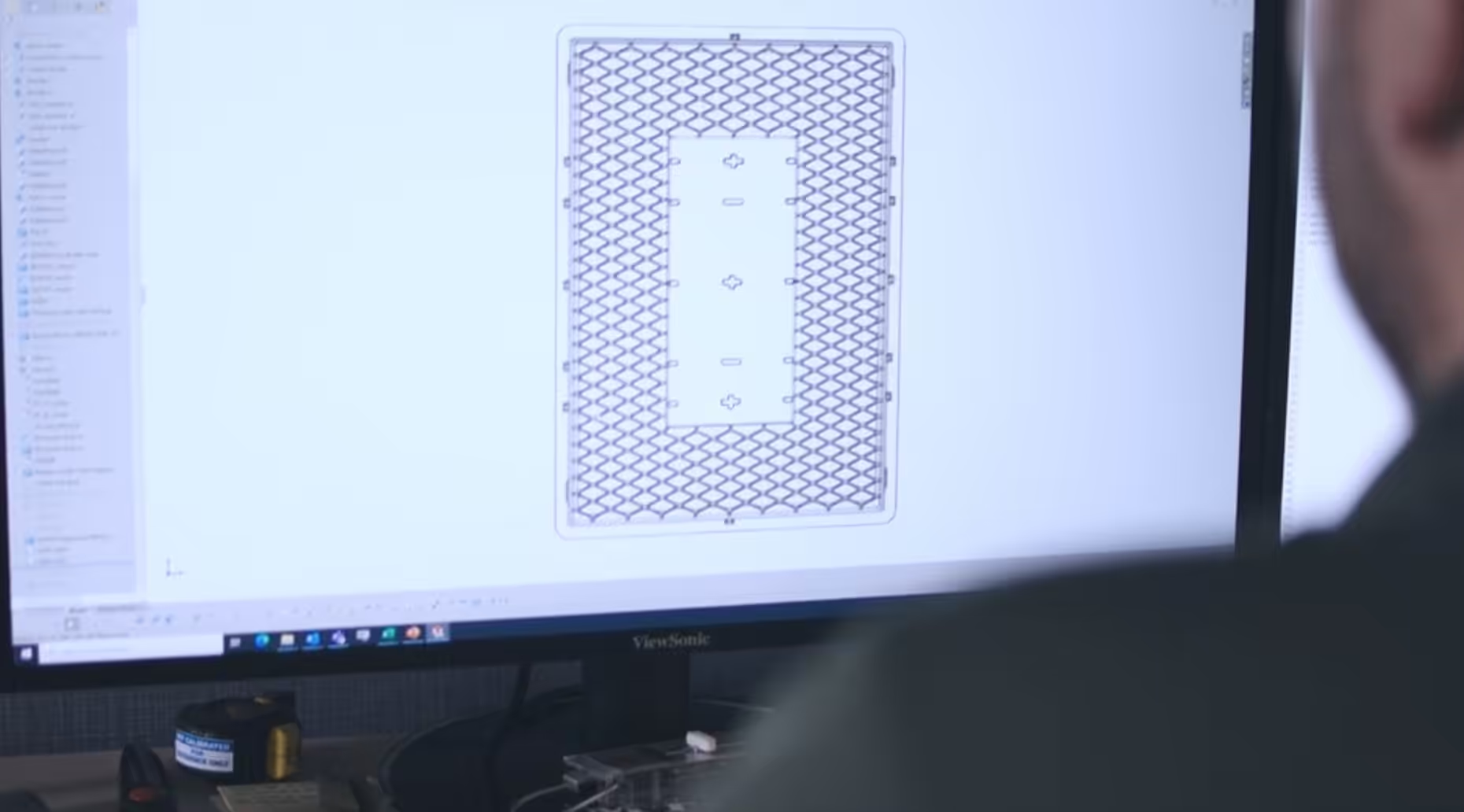

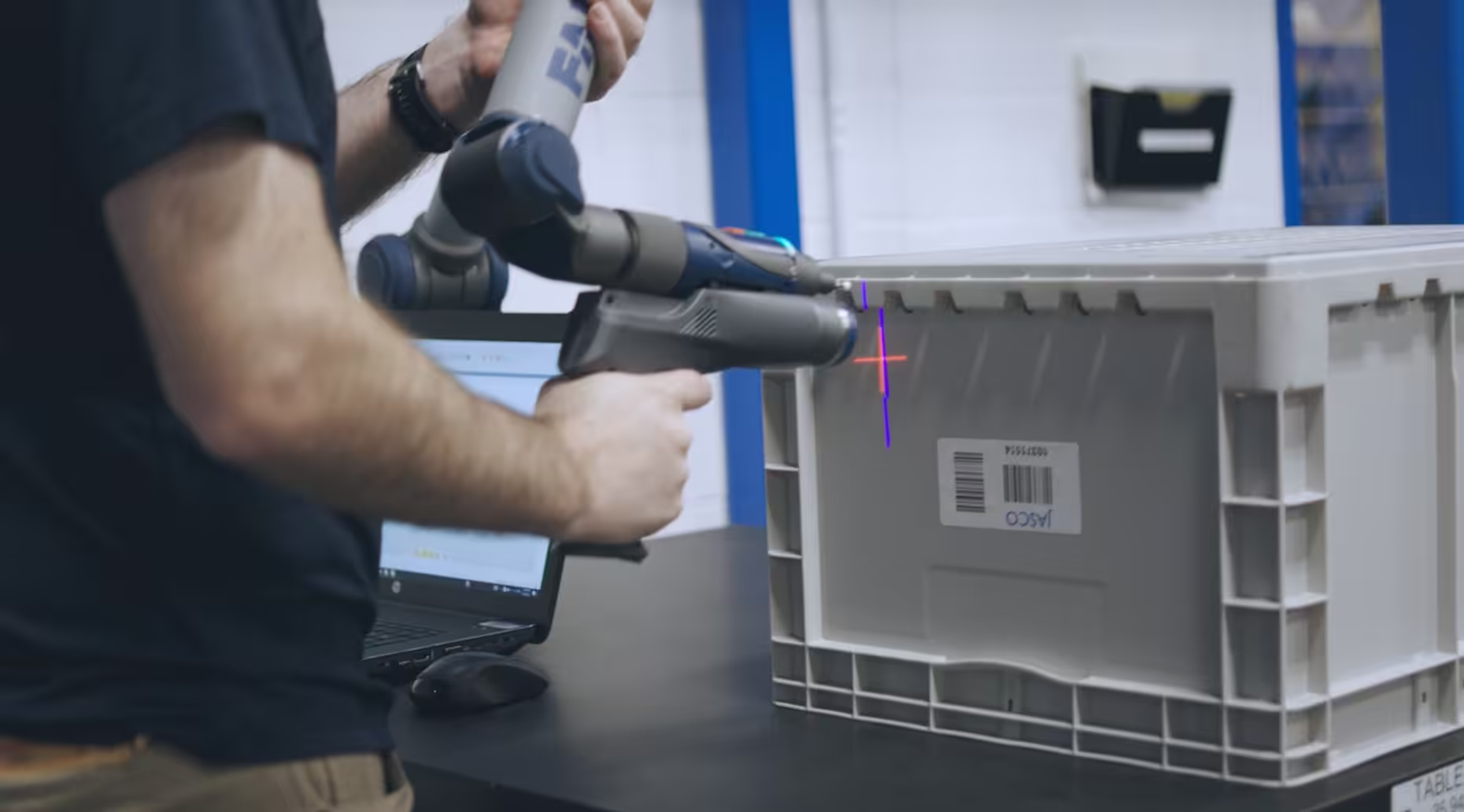

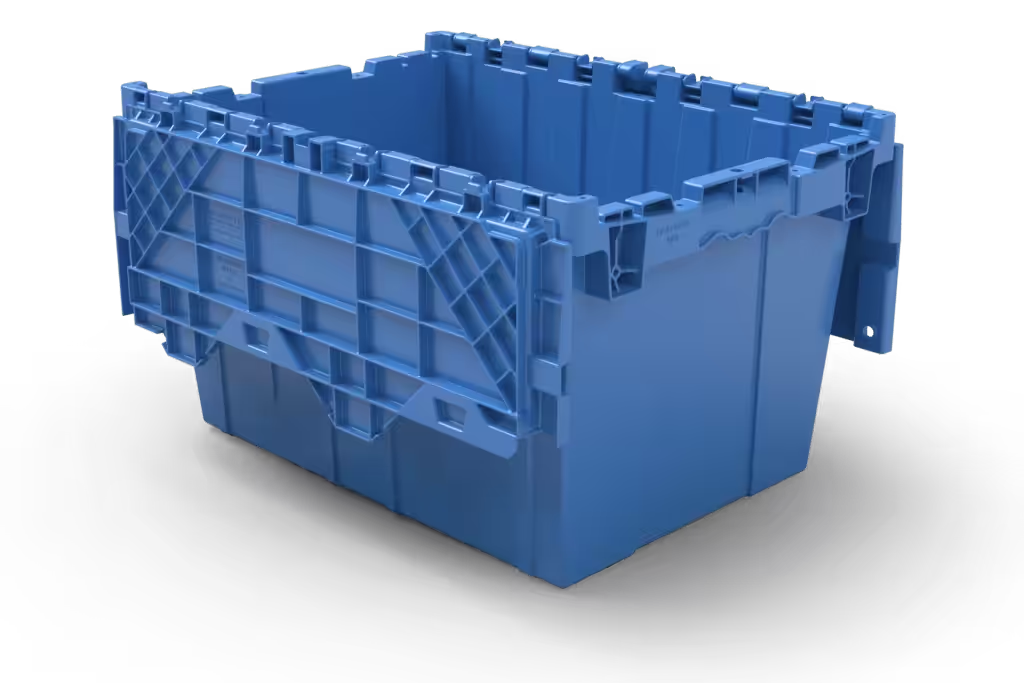

Custom Engineering

Packaging Solutions Built Precisely for Your Business

Our engineering team thrives on tackling new challenges. With decades of expertise and a relentless drive to innovate, we work closely with you to create custom packaging solutions that meet your unique needs. From concept to production, we’re passionate about solving problems that drive your success.